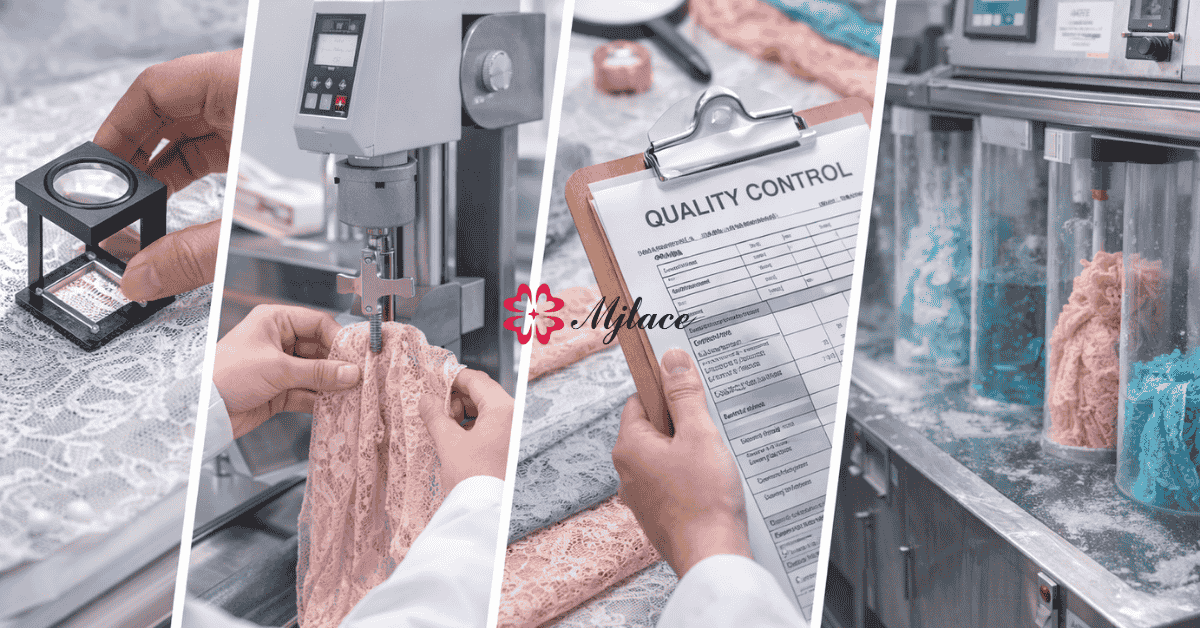

A Complete Guide to Quality Inspection, Testing, and International Compliance

In the global lace fabric industry, quality is not just an aesthetic requirement — it is a technical standard, a commercial promise, and a brand safeguard.

For apparel brands, sourcing managers, and textile buyers, lace quality directly affects garment durability, comfort, production yield, and customer satisfaction.

This article provides a comprehensive guide to lace fabric quality control and standards, covering inspection processes, testing methods, international certifications, and real-world quality risks in lace manufacturing.

Why Quality Control Is Critical in Lace Fabric Manufacturing

Lace fabrics are structurally complex textiles made through knitting, weaving, embroidery, or chemical processes. Compared with plain fabrics, lace has:

-

Open structures and fine yarns

-

Complex patterns and density variations

-

Higher sensitivity to tension, dyeing, and finishing

-

Greater risk of defects spreading during garment production

Without strict quality control, small defects can lead to:

-

Fabric breakage during cutting or sewing

-

Color inconsistency across production batches

-

High garment rejection rates

-

Costly reworks and delayed deliveries

For OEM and ODM lace suppliers, quality control is a competitive advantage, not just a compliance requirement.

Key Quality Factors in Lace Fabric Evaluation

Professional lace quality control focuses on five core dimensions:

1. Yarn & Raw Material Quality

-

Fiber composition accuracy (polyamide, polyester, cotton, elastane, viscose, etc.)

-

Yarn count consistency

-

Elastic recovery (for stretch lace)

-

Yarn strength and abrasion resistance

2. Structural Integrity

-

Stitch density uniformity

-

Pattern clarity and edge definition

-

Loop stability and knot security

-

Resistance to snagging and tearing

3. Appearance & Visual Quality

-

Surface cleanliness

-

Absence of oil stains or dye marks

-

Pattern symmetry

-

No broken motifs or missing embroidery threads

4. Color Accuracy & Fastness

-

Shade matching consistency

-

Color penetration depth

-

Resistance to washing, rubbing, light, and perspiration

5. Dimensional Stability

-

Shrinkage after washing

-

Width and length tolerance

-

Elastic recovery after stretching

Lace Fabric Quality Inspection Process (Step-by-Step)

1. Incoming Raw Material Inspection

Before production begins:

-

Yarn specifications verified

-

Fiber content confirmed

-

Elastic yarn tested for elongation and recovery

-

Color consistency checked (if pre-dyed yarns)

2. In-Process Production Inspection

During knitting, embroidery, or chemical lace production:

-

Machine tension monitoring

-

Pattern alignment checks

-

Continuous visual inspection

-

Defect recording and root-cause analysis

3. Grey Fabric Inspection

Before dyeing or finishing:

-

Structural defect detection

-

Hole, broken stitch, or pattern errors identified

-

Defect mapping on inspection reports

4. Finished Fabric Inspection

Final inspection typically follows the 4-point system or customized buyer standards, covering:

-

Visual defects

-

Color consistency

-

Measurement accuracy

-

Fabric hand feel and elasticity

Common Lace Fabric Defects and Causes

| Defect Type | Typical Cause |

|---|---|

| Broken motifs | Yarn tension imbalance |

| Color streaks | Uneven dye penetration |

| Oil stains | Machine lubrication issues |

| Pattern distortion | Incorrect machine setup |

| Elastic fatigue | Poor elastane quality |

| Edge curling | Improper finishing |

Early detection significantly reduces waste and reprocessing costs.

International Quality Standards for Lace Fabric

1. Color Fastness Standards

-

ISO 105 series

-

AATCC standards (U.S.)

-

Testing for washing, rubbing, light, perspiration

2. Dimensional Stability

-

ISO 6330 (washing and drying)

-

Buyer-specific tolerance requirements

3. Physical Performance Standards

-

Tensile strength

-

Tear resistance

-

Elastic recovery (especially for stretch lace)

4. Chemical Safety Standards

-

OEKO-TEX® Standard 100

-

REACH compliance (EU)

-

CPSIA (for children’s apparel)

-

AZO-free dye requirements

Lace Fabric Testing Methods Explained

Professional lace factories typically operate in-house laboratories or work with third-party labs.

Key tests include:

-

Color fastness to washing and rubbing

-

Elastic elongation and recovery testing

-

Fabric weight (GSM) verification

-

Shrinkage rate measurement

-

pH value testing

-

Formaldehyde content testing

Each test result is documented and traceable by batch.

Quality Control Standards by Lace Type

Different lace types require different quality benchmarks:

Stretch Lace

-

Elastic recovery ≥ specified %

-

No permanent deformation

-

Uniform stretch across width

Embroidery Lace

-

Secure thread anchoring

-

No loose embroidery threads

-

Backing fabric integrity

Chemical Lace

-

Complete base fabric removal

-

Clean edges without residue

-

Consistent motif thickness

Jacquard Lace

-

Pattern repeat accuracy

-

Stable loop formation

-

No floating yarns

Buyer Quality Requirements & Custom QC Protocols

Many international buyers apply:

-

AQL standards (2.5 / 4.0 or stricter)

-

Customized defect classification

-

Pre-shipment inspection (PSI)

-

Shade approval via lab dips

-

Golden sample confirmation

Experienced lace suppliers adapt their QC system to brand-specific requirements, ensuring smooth approval cycles.

How Quality Control Protects Brand Value

For fashion brands and garment manufacturers:

-

Stable lace quality reduces production risks

-

Fewer returns and customer complaints

-

Better garment fit and durability

-

Stronger brand reputation in premium markets

For suppliers:

-

Higher repeat order rates

-

Long-term OEM partnerships

-

Reduced claims and disputes

-

Sustainable growth through trust

Future Trends in Lace Quality Control

The lace industry is evolving toward:

-

Digital inspection systems

-

AI defect recognition

-

Automated color matching

-

Full traceability from yarn to shipment

-

Sustainable quality metrics (eco-dyes, water usage)

Quality control is no longer static — it is data-driven and system-based.

Conclusion: Quality Is the Foundation of Reliable Lace Supply

Lace fabric quality control is a multi-layered process combining craftsmanship, technology, and international standards.

Whether you are a fashion brand, importer, or sourcing professional, understanding lace quality standards ensures smarter decisions and long-term success.

At Meijara Textile, quality control is embedded into every step — from yarn selection to final shipment — ensuring lace fabrics that meet global standards and exceed expectations.