Introduction: Why Lace Machinery Matters in Modern Lace Manufacturing

In the lace fabric industry, design creativity alone is never enough. Behind every delicate lace pattern lies a complex system of machinery, equipment, and production technology that transforms yarn into high-value fabric.

For lace manufacturers, fashion brands, and sourcing professionals, understanding lace machinery is critical for:

-

Evaluating production capability

-

Ensuring fabric consistency and quality

-

Choosing the right lace type for each application

-

Scaling production efficiently

This article provides a comprehensive overview of lace machinery and equipment, covering traditional and modern machines, their functions, differences, and how they impact lace quality and cost.

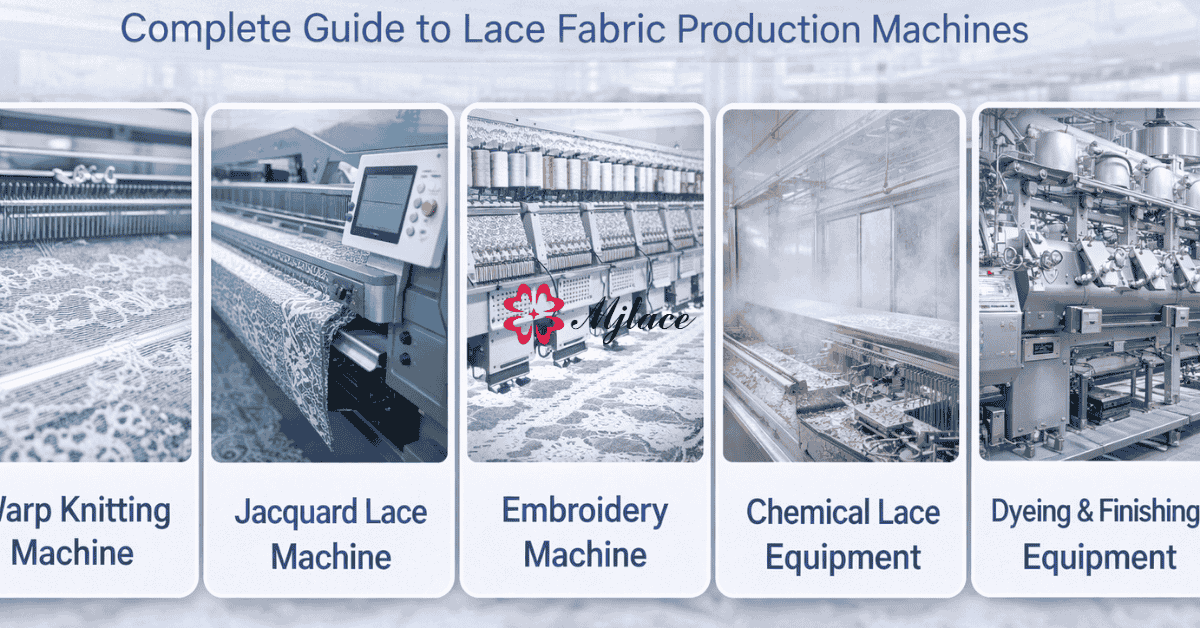

Overview of Lace Manufacturing Machinery

Lace machinery can be broadly divided into several categories based on production method and fabric structure:

-

Warp knitting machines

-

Jacquard lace machines

-

Embroidery machines

-

Chemical lace (Guipure) production equipment

-

Auxiliary equipment (dyeing, finishing, inspection)

Each type of machinery determines:

-

Lace pattern complexity

-

Fabric elasticity

-

Production speed

-

Cost structure

Understanding these machines helps buyers and designers match lace type with intended end use.

Warp Knitting Machines for Lace Production

What Is Warp Knitting Lace Machinery?

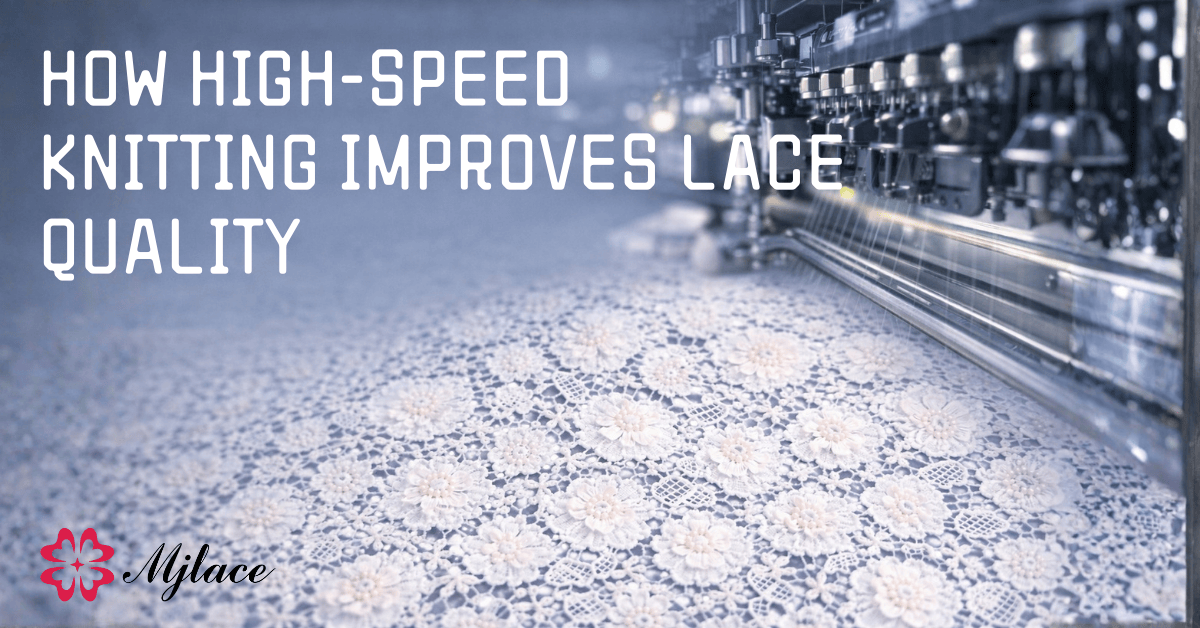

Warp knitting machines are among the most widely used machines in lace manufacturing today. They produce lace by interlacing yarns in a warp direction, allowing high-speed production with stable quality.

Common warp knitting lace machines include:

-

Raschel lace machines

-

Tricot machines

Advantages of Warp Knitting Lace Machines

-

High production efficiency

-

Excellent pattern repeat accuracy

-

Suitable for stretch and non-stretch lace

-

Consistent quality for large orders

Typical Applications

-

Stretch lace for lingerie and underwear

-

Apparel lace for dresses and blouses

-

Curtain and decorative lace

Jacquard Lace Machines: Precision Meets Creativity

What Is a Jacquard Lace Machine?

Jacquard lace machines integrate computerized pattern control systems that allow highly complex and customized lace designs. These machines control each yarn independently, enabling detailed motifs and large pattern repeats.

Key Features

-

Digital pattern programming

-

High design flexibility

-

Precise yarn control

-

Support for multi-color and layered effects

Why Jacquard Lace Machines Are Important

For premium lace manufacturers, Jacquard technology allows:

-

Faster design-to-production cycles

-

Custom OEM lace development

-

Small-batch or high-end lace production

Jacquard lace is commonly used in:

-

Bridal lace

-

Couture fashion

-

Luxury home textiles

Embroidery Machines for Lace Fabric

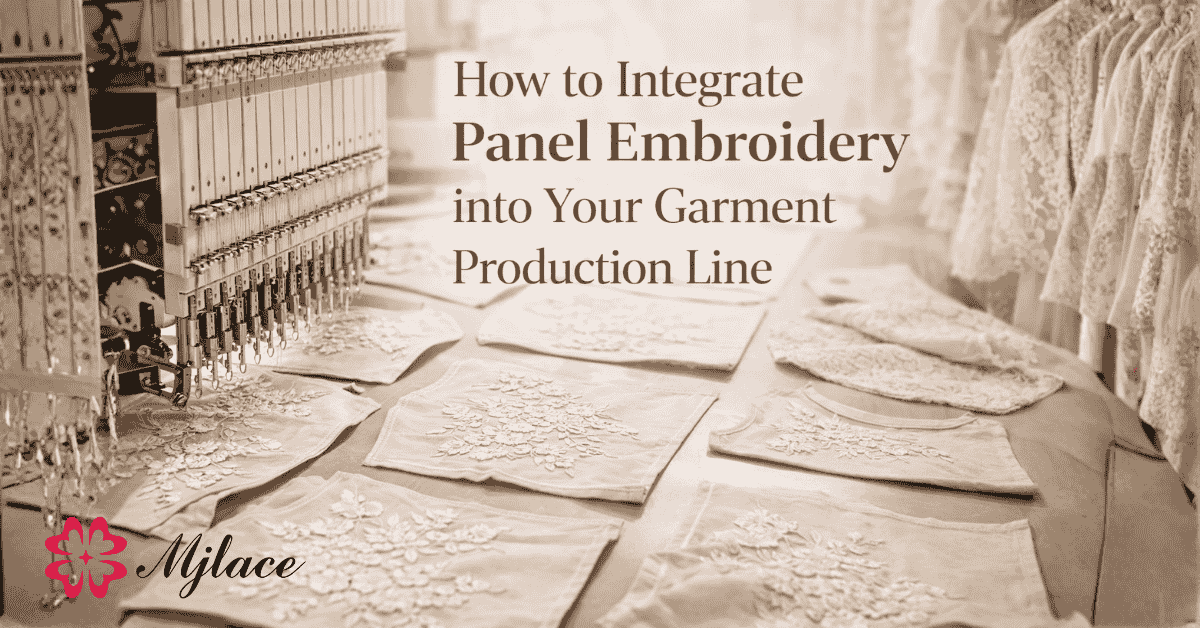

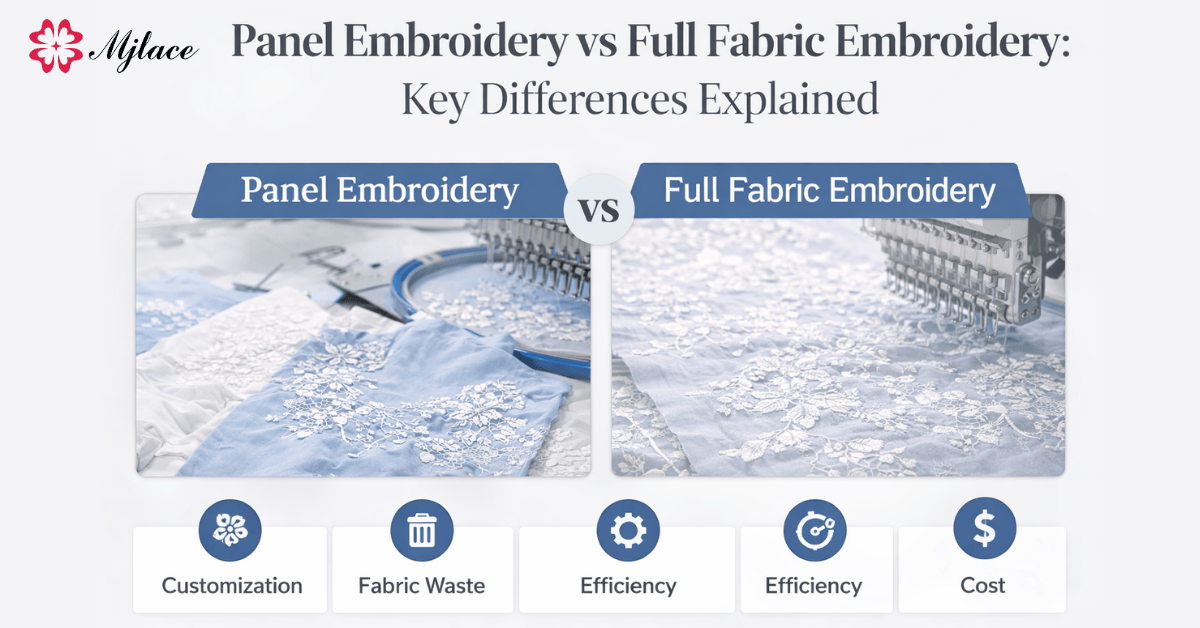

How Embroidery Lace Is Produced

Embroidery lace is created by stitching patterns onto a base fabric or water-soluble substrate using computerized embroidery machines.

Modern embroidery machines can:

-

Handle multi-head production

-

Execute intricate 3D embroidery

-

Combine sequins, beads, and metallic threads

Types of Embroidery Lace Equipment

-

Flat embroidery machineslace manufacturing equipment

-

Multi-head embroidery systems

-

Sequin and bead embroidery machines

Applications

-

Heavy embroidery lace

-

Bridal and evening wear lace

-

Decorative and statement textiles

Embroidery lace machinery is ideal for design-driven lace, where visual impact matters more than speed.

Chemical Lace (Guipure Lace) Production Equipment

What Is Chemical Lace Machinery?

Chemical lace, also known as Guipure lace, is produced using:

-

Embroidery machines on water-soluble fabric

-

Chemical washing equipment to dissolve the base fabric

This process leaves behind free-standing lace structures with bold patterns.

Key Equipment Involved

-

High-precision embroidery machines

-

Chemical treatment tanks

-

Washing and drying systems

Advantages

-

Thick, structured lace appearance

-

No visible net base

-

Ideal for trims, borders, and luxury garments

Dyeing and Finishing Equipment for Lace

Why Dyeing Equipment Matters for Lace

Lace fabric is delicate. Improper dyeing or finishing can cause:

-

Distortion

-

Color inconsistency

-

Yarn damage

Professional lace manufacturers use specialized dyeing machines designed for lightweight, open-structure fabrics.

Common Finishing Equipment

-

Low-tension dyeing machines

-

Heat-setting equipment

-

Softening and finishing machines

-

Width-setting machines

High-quality finishing enhances:

-

Hand feel

-

Color fastness

-

Dimensional stability

Quality Control & Inspection Equipment

Ensuring Consistency in Lace Production

Modern lace factories rely on inspection equipment to detect:

-

Pattern defects

-

Broken yarns

-

Color variations

-

Structural irregularities

Typical Quality Control Equipment

-

Fabric inspection machines

-

Light tables for pattern review

-

Digital measuring systems

Quality inspection is essential for:

-

Export compliance

-

Brand consistency

-

Long-term customer trust

Automation & Smart Lace Manufacturing

The Rise of Smart Lace Factories

With Industry 4.0, lace machinery is becoming:

-

Digitally connected

-

Data-driven

-

More energy-efficient

Smart lace equipment allows manufacturers to:

-

Monitor production in real time

-

Reduce material waste

-

Improve order traceability

Automation also shortens lead times and enhances repeatability—critical for global supply chains.

Choosing the Right Lace Machinery: A Buyer’s Perspective

For buyers and sourcing professionals, understanding machinery helps evaluate suppliers based on:

-

Technical capability

-

Design flexibility

-

Production capacity

-

Quality control level

A factory equipped with modern lace machinery is better positioned to deliver:

-

Stable quality

-

Custom designs

-

On-time delivery

Conclusion: Machinery as the Backbone of Lace Quality

Lace machinery and equipment form the foundation of every lace fabric, regardless of how beautiful the design appears on the surface.

From warp knitting machines to embroidery systems and smart finishing equipment, the right machinery:

-

Enhances design possibilities

-

Ensures production consistency

-

Supports scalable, sustainable manufacturing

For brands and buyers, understanding lace machinery is not just technical knowledge—it is a strategic advantage in sourcing and product development.