The development of lace fabric patterns and designs is one of the most crucial stages in lace manufacturing. It not only determines the visual characteristics of the lace fabric, but also its functionality, production feasibility, cost, and final application in clothing.

For fashion brands, designers, and purchasing managers, understanding the development process of lace patterns—from initial inspiration to final production—can significantly improve design efficiency, communication accuracy, and product success rates.

This guide provides a comprehensive explanation of the design, development, testing, and improvement process of lace patterns, covering the creative and technical aspects of lace fabric development.

What is the development of patterns and designs for lace fabrics ?

Lace pattern and design development refers to the process of transforming creative ideas into producible lace structures.

These include:

Pattern Design

Pattern repetition planning

Structural Engineering

Yarn and needlework selection

Sampling and revision

Compatibility with different lace machines

Unlike printed or woven fabrics, lace designs must balance aesthetics and structure. Each pattern must be both beautiful andtechnically feasible.

The role of lace patterns in fashion design

Definition of lace pattern:

Brand image (romantic, luxurious, modern, retro)

Clothing silhouette and drape

Transparency and coverage

Strength and comfort

Cost positioning (mass market vs. high-end market)

The carefully designed lace pattern can make the brand:

Stand out in a highly competitive market

Maintain consistency across all series.

Improve fit and wearing comfort

Reduce sampling error and delay

Inspiration for lace pattern design

3.1 Fashion and Trend Forecasting

Design inspiration often begins with:

Seasonal Fashion Trends Report

Fashion Show Series

Color forecast

Fabric Trend Board

These trends can influence the scale, density, and visual rhythm of patterns.

3.2 Nature and Art

Common sources of inspiration include:

Floral and plant elements

Geometric shapes

Architectural details

Cultural and historical allusions

3.3 Brand DNA and Market Positioning

Luxury wedding dress lace is quite different from the casual stretch lace commonly used in lingerie. Pattern design always begins with clearly defining the end use.

Lace pattern structure types

4.1 Full-body pattern

Continuous repetition

Suitable for dresses, blouses, and large pieces of fabric

Precise repeat alignment required

4.2 Borders and Fan Patterns

Single-sided or double-sided edge

Used for hem, collar, and cuffs

Requires a high level of technical precision

4.3 Layout and Panel Design

Designed specifically for specific clothing areas

Commonly seen in haute couture and wedding dresses

Often combined with embroidery

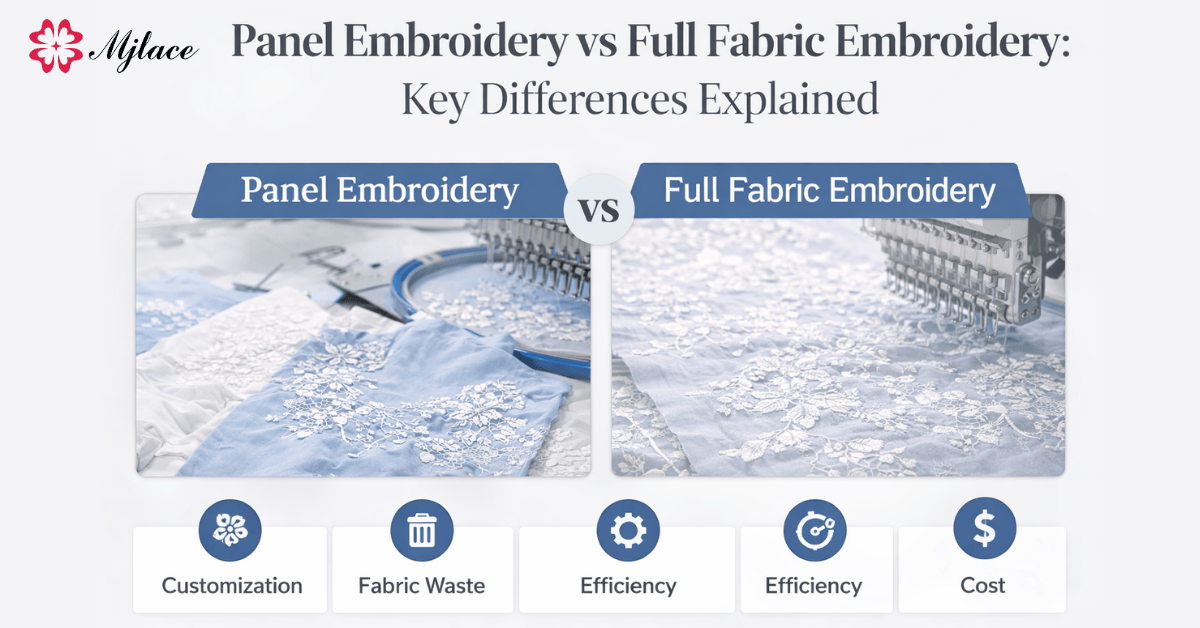

Digital pattern design in modern lace development

5.1 CAD Software in Lace Design

Modern lace pattern design relies heavily on computer-aided design (CAD) systems:

Pattern creation

Repeated calculation

Sewing Simulation

Yarn Path Visualization

This enables designers and manufacturers to:

Shorten development time

Improve accuracy

Quickly test multiple solutions

5.2 Jacquard Pattern Programming

The pattern of the jacquard lace must be converted to:

Machine-readable data

Yarn movement instructions

Stitch density control

This step directly affects:

Fabric stability

Pattern clarity

Production efficiency

Technical considerations in the development of lace patterns

6.1 Yarn Selection

Different yarns will have the following effects:

texture

shine

strength

Tensile properties

Commonly used yarns include:

nylon

Polyester fiber

cotton

Rayon

Spandex (used in elastic lace)

6.2 Pattern density and openness

Designers must weigh the following points:

Visual delicacy

Structural integrity

Tear resistance

Clothing durability

Overly open patterns may look nice, but they will fail abrasion resistance tests.

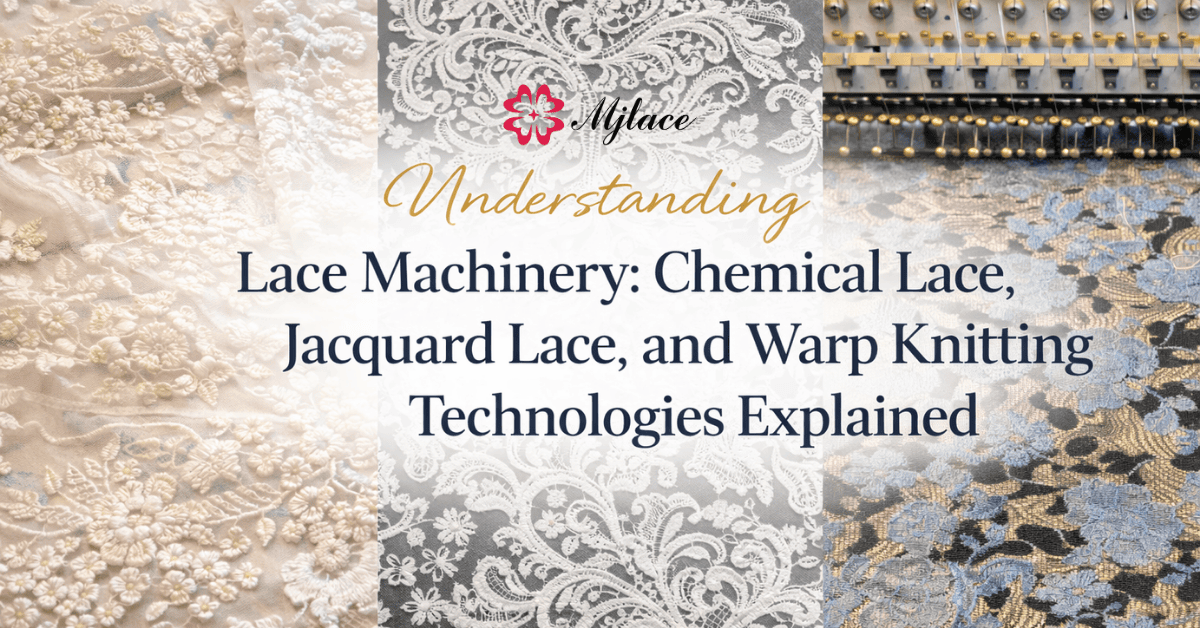

Development of patterns for different types of lace

7.1 Elastic Lace Pattern Design

Key points:

Elastic recovery

Pattern Distortion Control

Comfortable to wear

The pattern must be stretched evenly without deformation.

7.2 Jacquard lace pattern design

Key points:

Depth and texture

Multi-layer effect

Structural complexity

7.3 Embroidery and Lace Pattern Design

Key points:

Base Compatibility

Embroidery density

Line weight and layering

7.4 Chemical Lace Pattern Design

Key points:

Structural independence

Chemical process tolerance

Edge sharpness after dissolving the base fabric

Sample collection and prototype development

Sampling is a crucial validation phase.

8.1 Initial Sampling (Laboratory Impregnation and Structural Testing)

Pattern visibility

Yarn behavior

Structural stability

8.2 Adaptability and Applicability Testing

Pattern testing includes:

Garment Sample

Stretching and recovery test

Washing and abrasion tests

8.3 Mode Optimization

The revisions may include:

Adjust pattern size

Adjust stitch density

Change the yarn combination

Collaboration between designers and manufacturers

Successful lace pattern development depends on close collaboration.

Manufacturer provides:

Technical feasibility insights

Machine limitations

Cost optimization suggestions

Provided by the designer:

Creative Director

Brand Requirements

Market expectations

This collaborative approach can minimize risks and improve the final outcome.

Common challenges in lace pattern design

Pattern deformation during stretching

Inconsistent alignment of repeat sequences

Overly complex designs will increase costs.

Limited machine compatibility

Poor communication between the design and production teams

Experienced manufacturers play a crucial role in addressing these issues early on.

OEM and custom lace pattern development

For brands seeking differentiation, OEM pattern development can be offered:

Exclusive design

Controlled intellectual property ownership

Brand exclusive pattern

Custom pattern development typically includes:

Conceptual discussion

CAD design

sampling

Approval and production scale

Future Trends in Lace Pattern Design

Digital-first pattern creation

Sustainable yarn integration

Lightweight and durable structure

Multi-functional lace suitable for fashion and sportswear

Customizable patterns available, suitable for small-batch production.

Conclusion: Why Pattern and Design Development is Crucial

Pattern and design development is the foundation of high-quality lace fabrics. It connects creativity and engineering, transforming ideas into wearable, producible textiles.

For fashion brands, mastering lace pattern design can bring the following benefits:

Better product consistency

Faster development cycle

A stronger brand image

Higher market competitiveness

For manufacturers like Meijara Textile, deep expertise in lace pattern development ensures reliable OEM solutions, superior technology, and long-term partnerships with global brands.