Lace is one of the most versatile and decorative textiles in the fashion industry. From exquisite wedding dresses to practical lingerie, from hand embroidery to advanced jacquard weaving, lace exists in a variety of forms, structures, and manufacturing methods.

However, many designers, buyers, and even manufacturers often ask the same question:

How many types of lace fabric are there? How are they classified?

This guide provides a comprehensive and professional overview of the types and categories of lace,explaining it from the perspectives of structure, materials, production methods, and applications . It also helps buyers and designers select the right lace fabrics for different garments and markets.

What is lace fabric ?

Lace is a decorative textile made by winding, twisting, or embroidering threads into open-work patterns. Unlike irregular fabrics, lace is characterized by:

Hollow design

Floral, geometric or decorative patterns

Lightweight and breathable structure

Decorative and functional uses

Historically, lace was handmade using needles or spools of thread. Today, depending on the desired effect and cost, lace can be handmade, machine-made, knitted, woven, embroidered, or chemically treated.

How many types of lace fabric are there?

Although there are no unified official figures, lace fabrics are generally divided into the following four main dimensions:

Structure and elasticity

Through manufacturing methods

Through pattern forming technology

According to material composition

Each category contains multiple types of lace. Below is a clear and systematic classificationcommonly used by professional lace manufacturers and global buyers .

Lace types classified by structure and elasticity

1. Elastic lace fabric

Elastic lace contains elastic fibers such as spandex or elastic fibers, which allows the fabric to stretch and return to its original shape.

Main features:

High elasticity and comfort

Fitted style

Clothing that is perfect for high-intensity exercise

Common applications:

Underwear and intimate apparel

bras and panties

shapewear

Sports Apparel Details

Elastic lace is typically produced by knitting machines or elastic warp knitting machines, making it ideal for mass production and ensuring consistent quality.

2. Non-elastic lace fabric

Non-elastic lace contains no elastic fibersand relies entirely on its structural design to maintain its elasticity.

Main features:

Stable shape

Clear and distinct pattern

Elegant drape

Common applications:

bridal gown

Evening dress

Fashion Clothing

Decorative trim

When structural, shape, and visual precisionare more important than flexibility , non-elastic lace is a better choice.

Lace types classified by manufacturing method

1. Embroidered lace

Embroidered laceis made by sewing lace patterns onto a base fabric or temporary backing.

feature:

Rich and three-dimensional appearance

It can include beads, sequins, rope, or thread.

Suitable for custom and luxury designs

Application areas:

wedding dress

High fashion

Traditional clothing

Embroidered lace offers maximum design freedom, making it popular in the high-end market.

2. Jacquard lace

Jacquard laceis produced using jacquard weaving or knitting machines, which can digitally program complex patterns.

feature:

High consistency

Repeatable patterns

Suitable for mass production

Application areas:

Fashion Clothing

Lingerie lace patchwork

ready-to-wear

Jacquard lace combines design sophistication with production efficiency, making it an ideal choice for global brands.

3. Guipure Lace (chemical lace)

Chemical lace ismade by embroidering patterns onto a water-soluble or chemically removable base fabric , which is then dissolved.

feature:

No visible ground cover

Striking and structured patterns

Heavy and luxurious appearance

Application areas:

bridal gown

Decorative trim

Eye-catching fashion items

Because of its tough texture, this type of lace is often compared to cotton lace.

Types of lace classified by pattern and technique

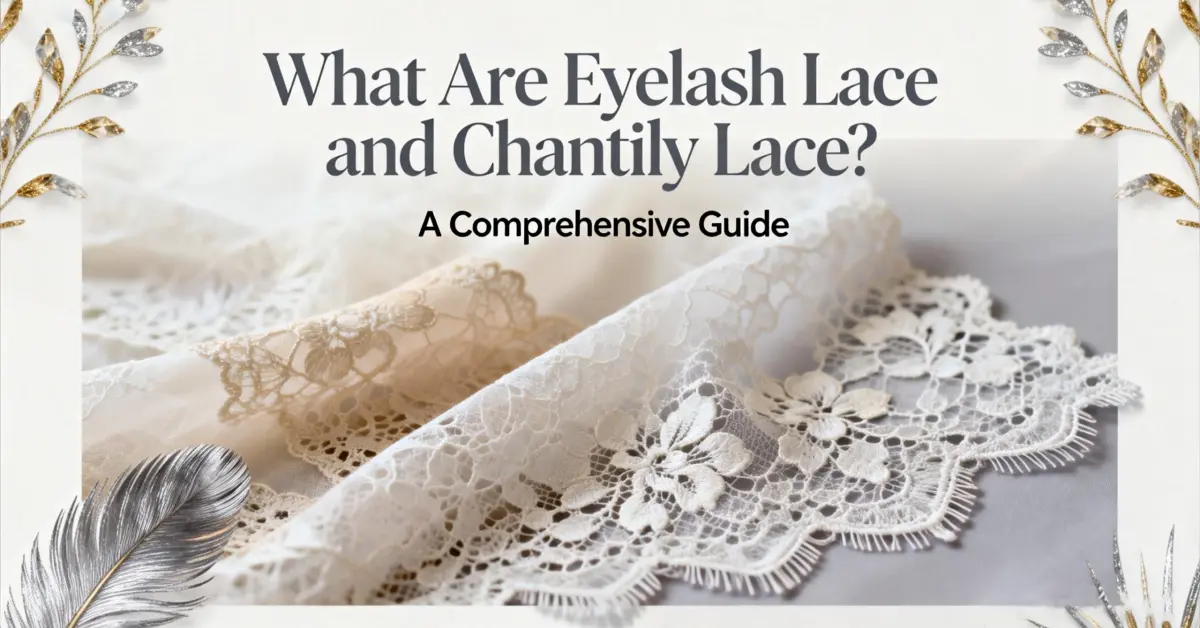

1. Chantilly Lacey

Chantilly laceis renownedfor its fine mesh base and delicate floral patterns .

Main features:

Light and soft

Elegant and romantic

High transparency

Application areas:

Bridal Veil

wedding dress

Luxury fashion layering

Chantilly lace represents classic European lace craftsmanship.

2. Rope-like lace

Rope lace is characterized by thicker ropes that outline a raised contour.

feature:

Strong mode definition

3D effect

Advanced visual depth

It is often used in high-end wedding dresses and evening gowns.

3. Multicolored lace

This lace incorporates multiple thread colors within a single design.

Application areas:

Fashionable and avant-garde clothing

Decorative collectibles

Seasonal Design

Multicolored lace allows designers to express their creative ideas and lead trends in aesthetic concepts.

Lace types classified by material composition

1. Cotton lace

Cotton laceis breathable, natural, and soft.

Advantages:

Skin-friendly

Environmental awareness

Comfortable for everyday wear

Commonly used in casual wear, children's clothing, and decorative trims.

2. Polyester lace

Polyester lace is the most commonly used type in commercial production.

Advantages:

Durable

High cost performance

High color fastness and good stability

It is ideal for large-scale production and export markets.

3. Nylon-blend lace

Blended lace combines nylon, polyester, cotton, or spandex to optimize performance.

benefit:

Balanced stretch and strength

Wide range of uses

Enhanced durability

Key Comparisons (Popular Search Topics)

Elastic lace and non-elastic lace

Elastic lace = Comfortable and flexible

Non-elastic lace = crisp and structured, elegant and graceful

Embroidered lace and jacquard lace

Embroidery = Handmade feel, highly customized

Jacquard technology = scalable, consistent, and efficient

Chemical lace vs. cotton lace

Chemical lace = bold, structured, and highly decorative

Cotton lace = soft, breathable, natural

How to choose the right type of shoelaces?

When choosing lace fabric, please consider the following factors:

Clothing Function

Target markets (luxury market and mass market)

Comfort requirements

Design complexity

Yield

Professional lace manufacturers typically offer OEM customization servicesto help brands find the right type of lace that matches their design philosophy.

Final words

Understanding the types and categories of lace is crucial for designers, buyers, and brands. Each type of lace fabric has its own structure, production logic, and market positioning.

This guide aims to lay the foundation for in-depth exploration of various lace types, manufacturing techniques, and sourcing strategies .