Lace fabric is one of the most versatile and decorative textiles in the fashion and garment industry. Known for its intricate patterns, lightweight structure, and elegant appearance, lace has been used for centuries in apparel, lingerie, bridalwear, and decorative textiles.

In this comprehensive guide, we will explain what lace fabric is, explore different types of lace fabrics, compare stretch and non-stretch lace, break down the lace manufacturing process, and provide practical insights on choosing high-quality lace fabric for garments. This article also covers lace fabric terminology and quality standards commonly used in the global textile industry.

What Is Lace Fabric?

Lace fabric is a decorative textile characterized by openwork patterns created through weaving, knitting, embroidery, or chemical processes. Unlike solid fabrics, lace is designed with spaces between yarns, forming floral, geometric, or ornamental motifs.

Originally handcrafted, modern lace fabric is now produced using advanced machinery, allowing manufacturers to achieve consistent quality, complex designs, and scalable production volumes.

Key Characteristics of Lace Fabric

-

Open, patterned structure

-

Lightweight and breathable

-

Decorative and ornamental appearance

-

Available in stretch and non-stretch versions

-

Widely used in fashion and functional applications

Types of Lace Fabric Explained

Lace fabrics can be classified based on manufacturing technique, material, and structure. Below are some of the most common lace fabric types used in the market today.

1. Stretch Lace Fabric

Stretch lace is made by blending elastic fibers such as spandex or elastane with nylon or polyester yarns. This type of lace offers flexibility and comfort, making it ideal for:

-

Lingerie and underwear

-

Intimate apparel

-

Body-hugging garments

-

Activewear fashion details

2. Non-Stretch Lace Fabric

Non-stretch lace is made without elastic fibers and provides a more structured appearance. It is commonly used in:

-

Bridal gowns

-

Evening dresses

-

Formal wear

-

Decorative trims

3. Jacquard Lace

Jacquard lace is produced on jacquard machines, allowing complex and highly detailed patterns. It is known for durability and dimensional texture.

4. Embroidered Lace

Embroidered lace is created by stitching lace patterns onto a base fabric such as mesh, tulle, or organza. This technique offers high design flexibility and premium aesthetics.

5. Chemical Lace (Burn-Out Lace)

Chemical lace is made by dissolving the base fabric through a chemical process, leaving behind freestanding lace patterns. It is widely used in high-end fashion and couture.

Difference Between Stretch Lace and Non-Stretch Lace

Understanding the difference between stretch lace and non-stretch lace is crucial when selecting materials for garment production.

| Feature | Stretch Lace | Non-Stretch Lace |

|---|---|---|

| Elasticity | High | None |

| Comfort | Excellent | Moderate |

| Structure | Soft, flexible | Firm, structured |

| Applications | Lingerie, fitted garments | Bridal, formal wear |

| Sewing Difficulty | Medium | Easier for structured designs |

Choosing the right type depends on garment function, fit requirements, and design intent.

Lace Fabric Manufacturing Process

The lace fabric manufacturing process varies depending on the type of lace being produced, but it generally includes the following steps:

1. Yarn Selection

High-quality lace starts with carefully selected yarns such as nylon, polyester, cotton, or blended fibers.

2. Design Development

Designs are created digitally or manually, defining pattern density, repeat size, and motif layout.

3. Lace Production

Lace is produced using specialized machines such as:

-

Raschel warp knitting machines

-

Jacquard lace machines

-

Embroidery machines

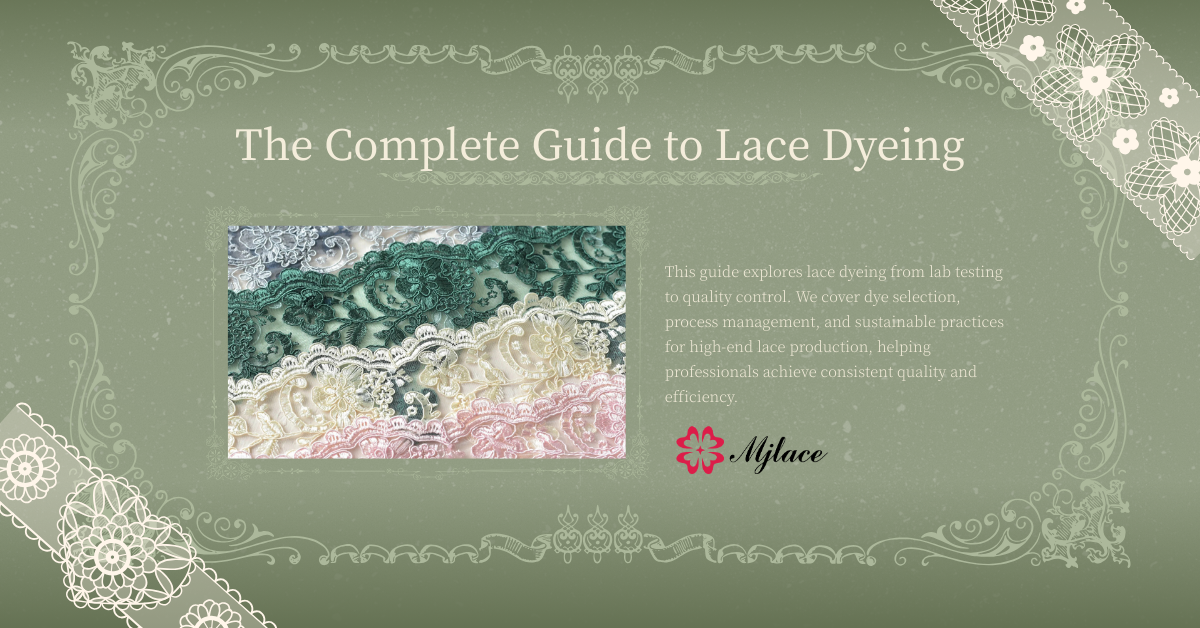

4. Dyeing and Finishing

After production, lace fabric undergoes dyeing, softening, heat setting, and surface finishing to achieve the desired color and hand feel.

5. Quality Inspection

Final inspection ensures consistency in pattern, elasticity, colorfastness, and overall fabric performance.

How to Choose Lace Fabric for Garments

When sourcing lace fabric for garments, buyers and designers should consider the following factors:

1. End Use

-

Lingerie requires softness and stretch

-

Bridal wear requires structure and elegance

-

Ready-to-wear fashion needs durability and cost efficiency

2. Fabric Composition

Different fiber compositions affect comfort, appearance, and care requirements.

3. Pattern Density

Denser patterns provide better coverage, while open patterns offer breathability and delicacy.

4. Color Consistency

Uniform dyeing is critical for large-scale garment production.

5. Supplier Capability

Choose manufacturers with strong R&D, sampling, and OEM customization capabilities.

Lace Fabric Terminology Explained

Understanding common lace fabric terms helps buyers communicate clearly with suppliers.

-

GSM: Fabric weight per square meter

-

Repeat Size: Pattern repetition measurement

-

Hand Feel: Texture and softness of the fabric

-

Elastic Recovery: Ability of stretch lace to return to original shape

-

Warp / Weft: Yarn directions in lace construction

Lace Fabric Quality Standards

High-quality lace fabric should meet industry standards for performance and durability. Common quality checkpoints include:

-

Colorfastness to washing and rubbing

-

Tensile strength and elasticity

-

Dimensional stability

-

Pattern uniformity

-

Compliance with international textile standards

Manufacturers serving global brands typically follow strict internal quality control systems to ensure consistency across batches.

Final Thoughts

Lace fabric is a sophisticated textile that combines artistry, technology, and functionality. From stretch lace for lingerie to structured lace for bridal gowns, understanding lace fabric knowledge helps designers, buyers, and brands make better sourcing decisions.

As lace continues to evolve with new materials and technologies, working with an experienced lace fabric manufacturer ensures access to high-quality materials, innovative designs, and reliable production support.